Engineering & Support Services

Leveraging years of experience in insert molding, we offer advanced solutions that blend precision with efficiency. Our deep expertise allows us to deliver high-quality components that integrate seamlessly into your products, enhancing both functionality and durability. Explore how our knowledge and proven techniques can streamline your manufacturing process and support your project’s success.

You can count on us for cutting-edge solutions and exceptional support to elevate your engineering projects.

By leveraging advanced software, this analysis predicts how molten plastic will flow through a mold cavity, enabling our engineers to identify potential issues before manufacturing begins. The simulation considers factors such as material properties, mold design, and processing conditions to create accurate, real-world scenarios.

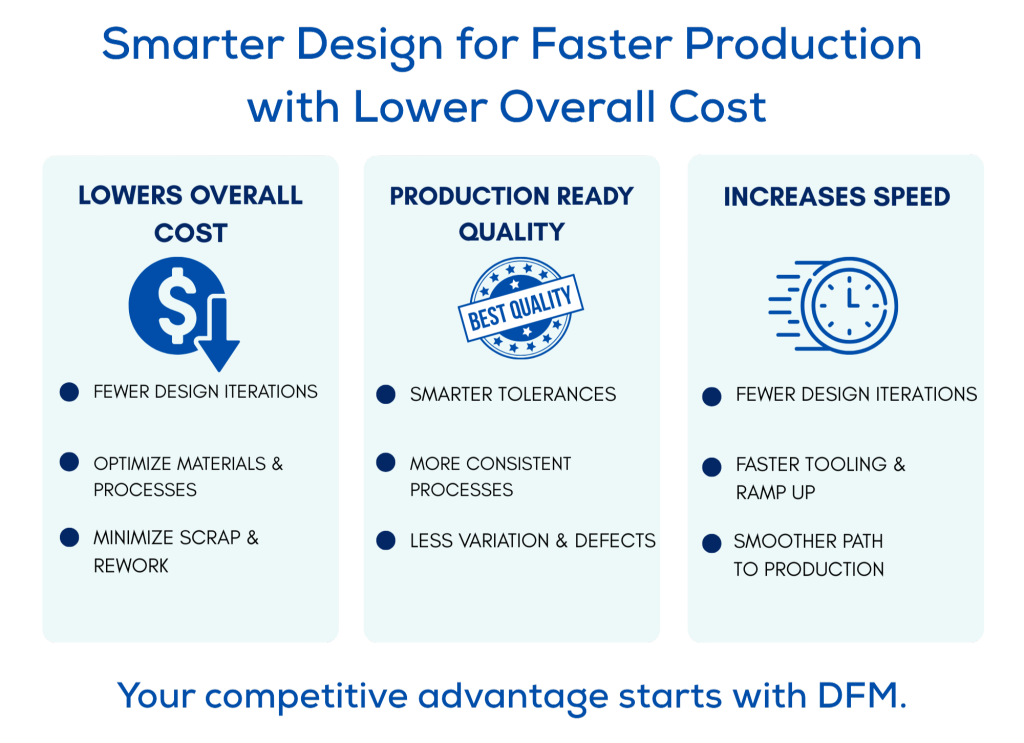

Smarter DFM

Engineering designs optimized for manufacturability, performance, and faster time to market.

Resilient Supply Chains

Flexible and reliable sourcing and production that keeps your projects on schedule.

Lower Overall Cost

Minimizing overall expenses through efficient design, quality tooling, and turnkey solutions.

At Relucent, engineering is a core part of how we support our customers. Our team works closely with customers early in the development process to help ensure parts are manufacturable, scalable, and aligned with performance, quality, and cost expectations.

Whether a design is in its early stages or further along in development, our engineers collaborate with customers to identify potential risks, improve manufacturability, and support a smooth transition into production. The goal is to reduce surprises, limit rework, and set programs up for long term success.

Engineering support that starts with manufacturability.

Design for Manufacturability, or DFM, is central to our engineering approach. By reviewing part designs before tooling is finalized, our team helps identify opportunities to improve part geometry, material flow, and overall process stability.

Early DFM involvement allows potential issues to be addressed before they become costly problems. This leads to more efficient tooling, more consistent parts, and a faster path to production.

Our engineering team works alongside customers throughout the development cycle, not just at handoff. Early collaboration allows potential risks to be identified while changes are still easy to make. As programs move forward, engineering remains engaged to ensure tooling, materials, and processes are aligned with production realities.